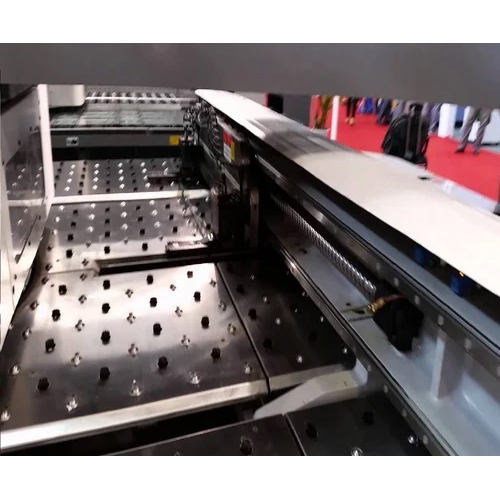

Punching CNC Job Work

Punching CNC Job Work Specification

- Custom Design Support

- Available

- Service Customization

- Yes

- Packaging Type

- Standard/Customized Packaging

- Production Capacity

- High Volume and Small Batch

- Finish Type

- Powder Coated, Painted, and Raw

- Cutting Speed

- High Speed Automated

- Max Punching Accuracy

- ±0.1 mm

- Sheet Thickness Range

- Up to 6 mm

- Tolerance

- As per client specification

Punching CNC Job Work Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 5 Days

About Punching CNC Job Work

Punching CNC Job Work features dominant capabilities with enviable precision and premier results, earning favorable reviews across India. Sizzling accuracy up to 0.1 mm with a sheet thickness range of up to 6 mm makes us the go-to exporter, manufacturer, supplier, and service provider. Grab yours now with custom design support, high-volume or small batch production, and finishes ranging from powder coated to painted or raw. Automated high-speed punching ensures peak efficiency and tailored tolerances. Packaging is available in standard or customized formats to fit every need. Service customization is our specialty.

Versatile CNC Punching: Usage, Applications & Features

Punching CNC Job Work is ideal for precision tasks in manufacturing, automotive, furniture, and electrical industries. Its advanced machine features include automated high-speed cutting and superior accuracy, allowing for material versatility up to 6 mm thick. Applications range from large-scale factory production to bespoke design projects, providing solutions at workshops, plants, and construction sites. By supporting both high-volume and small batches, it meets requirements for custom manufacturing, rapid prototyping, and bulk assembly jobs.

Certifications, Supply Ability & Export Markets

We offer CNC punching services certified for quality assurance and consistent accuracy. With a robust supply ability, we handle shipped goods for bulk and small batch orders. Main export markets include Asia, Europe, and the Middle East. Our List price structure ensures the lowest price for premier services, with packaging tailored for international delivery. Each order is shipped promptly and supported with standard or customized packaging to guarantee product safety, meeting global standards for reliability and precision.

Versatile CNC Punching: Usage, Applications & Features

Punching CNC Job Work is ideal for precision tasks in manufacturing, automotive, furniture, and electrical industries. Its advanced machine features include automated high-speed cutting and superior accuracy, allowing for material versatility up to 6 mm thick. Applications range from large-scale factory production to bespoke design projects, providing solutions at workshops, plants, and construction sites. By supporting both high-volume and small batches, it meets requirements for custom manufacturing, rapid prototyping, and bulk assembly jobs.

Certifications, Supply Ability & Export Markets

We offer CNC punching services certified for quality assurance and consistent accuracy. With a robust supply ability, we handle shipped goods for bulk and small batch orders. Main export markets include Asia, Europe, and the Middle East. Our List price structure ensures the lowest price for premier services, with packaging tailored for international delivery. Each order is shipped promptly and supported with standard or customized packaging to guarantee product safety, meeting global standards for reliability and precision.

FAQs of Punching CNC Job Work:

Q: How does CNC punching ensure high accuracy in job work?

A: CNC punching employs automated controls and precise tooling, achieving dominant accuracy up to 0.1 mm, which minimizes errors and delivers uniform, enviable quality for every project.Q: What materials and thicknesses are supported for punching?

A: The service supports various metals with sheet thicknesses up to 6 mm, making it suitable for steel, aluminum, and other alloys in both raw and finished forms as required.Q: Where are the main application places for CNC punched parts?

A: CNC punched parts are extensively used in manufacturing facilities, automotive workshops, construction sites, and electrical equipment assembly plants due to their precise dimensions and excellent finish.Q: What is the process for customizing punching services?

A: Customization begins with client specifications for design, tolerance, finish, and batch size. Our team collaborates to ensure tailored solutions, packaging preferences, and delivery schedules for each order.Q: What are the benefits of choosing your CNC punching service?

A: Clients benefit from premier accuracy, rapid turnaround, flexible production volumes, multiple finish options, certified quality, and competitive pricing. Custom support and reliable packaging solutions enhance every experience.

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 5 Days

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS