Precision Turned Components

Precision Turned Components Specification

- Size

- Standard

- Usage

- Industrial

- Material

- Metal

- Surface

- Polishing

- Product Type

- Precision Turned Components

- Use

- Industrial

- Color

- Silver

Precision Turned Components Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Precision Turned Components

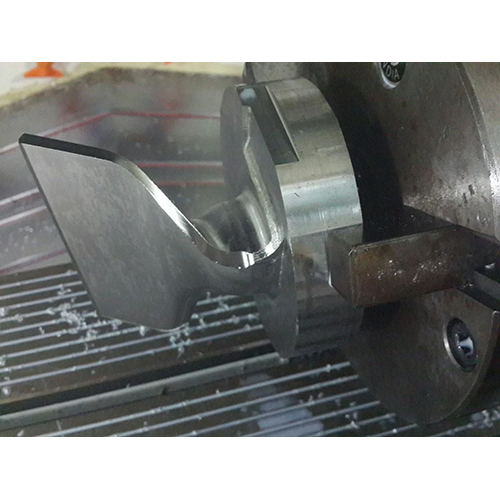

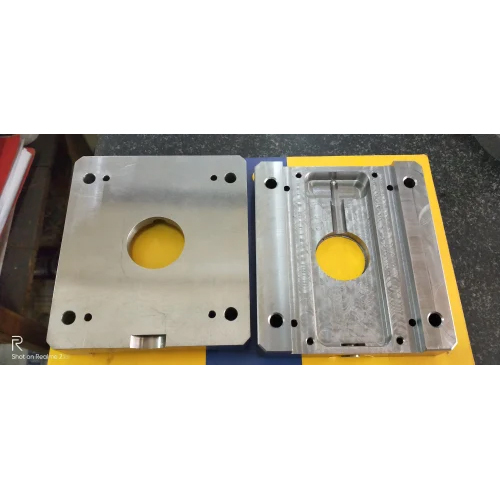

High-accuracy machined parts made using CNC turning processes to precisely match design parameters are known as precision-turned components. Constructed from materials like titanium, brass, aluminium, and stainless steel, they have crucial components like cutting tools, spindles, and guiding systems that guarantee accurate machining and shaping. These parts, which include shafts, gears, and bushings, are well-known for their strength, dependability, and longevity. Utilised in a variety of sectors, including electronics, automotive, aerospace, and medicine, they come in a variety of sizes and shapes and provide high-quality, adaptable, and efficient performance.

FAQs of Precision Turned Components:

Q: What are the primary uses of Precision Turned Components?

A: Precision Turned Components are designed for industrial use, providing high-quality performance and reliability in industrial settings.Q: What is the surface finish of Precision Turned Components?

A: The surface of Precision Turned Components is polished to ensure a smooth and sleek appearance.Q: What is the color of Precision Turned Components?

A: Precision Turned Components come in a silver color, adding a professional and versatile look.Q: What size are the Precision Turned Components available in?

A: The Precision Turned Components are available in standard sizes to cater to a wide range of industrial applications.Q: What material are Precision Turned Components made of?

A: Precision Turned Components are crafted from high-quality metal, ensuring durability and strength in industrial usage.

Price 2000 INR/ Piece

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Cnc Turned Components Category

Cnc Turned Components

Price 20000 INR / Piece

Minimum Order Quantity : 10

Use : Industrial

Material : Stainless Steel

Size : Standard

Color : Silver

Cnc Precision Components

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Use : Industrial

Material : Metal

Size : Standard

Color : Silver

Cnc Machined Components Job Work

Price 3000 INR / Piece

Minimum Order Quantity : 10 Pieces

Use : Industrial

Material : Metal

Size : Standard

Color : Silver

Cnc Machined Components

Price 30000 INR / Piece

Minimum Order Quantity : 1 Piece

Use : Industrial

Material : Metal

Size : Standard

Color : Silver

Send Inquiry

Send Inquiry Send SMS

Send SMS