Specification

- उपयोग

- Industrial

- मटेरियल

- साइज

- Standard

- प्रॉडक्ट टाइप

- Tip And Die For Cable Industry

- रंग

- Silver

- वारंटी

- yes

Trade Information

- Minimum Order Quantity

- 1 Number

- एफओबी पोर्ट

- surat

- भुगतान की शर्तें

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- नमूना उपलब्ध

- No

- नमूना नीति

- पैकेजिंग का विवरण

- Finished job work components are similarly packed to maintain quality, utilizing protective coverings and secure boxing for efficient dispatch and receipt.

- मुख्य निर्यात बाजार

- , , , , , , , ,

- मुख्य घरेलू बाज़ार

- प्रमाणपत्र

- ISO 9001:2015 Certification: Indicates that the manufacturer follows stringent quality management systems for the design, production, and delivery of turret punch press tools, ensuring consistent product quality and customer satisfaction

About

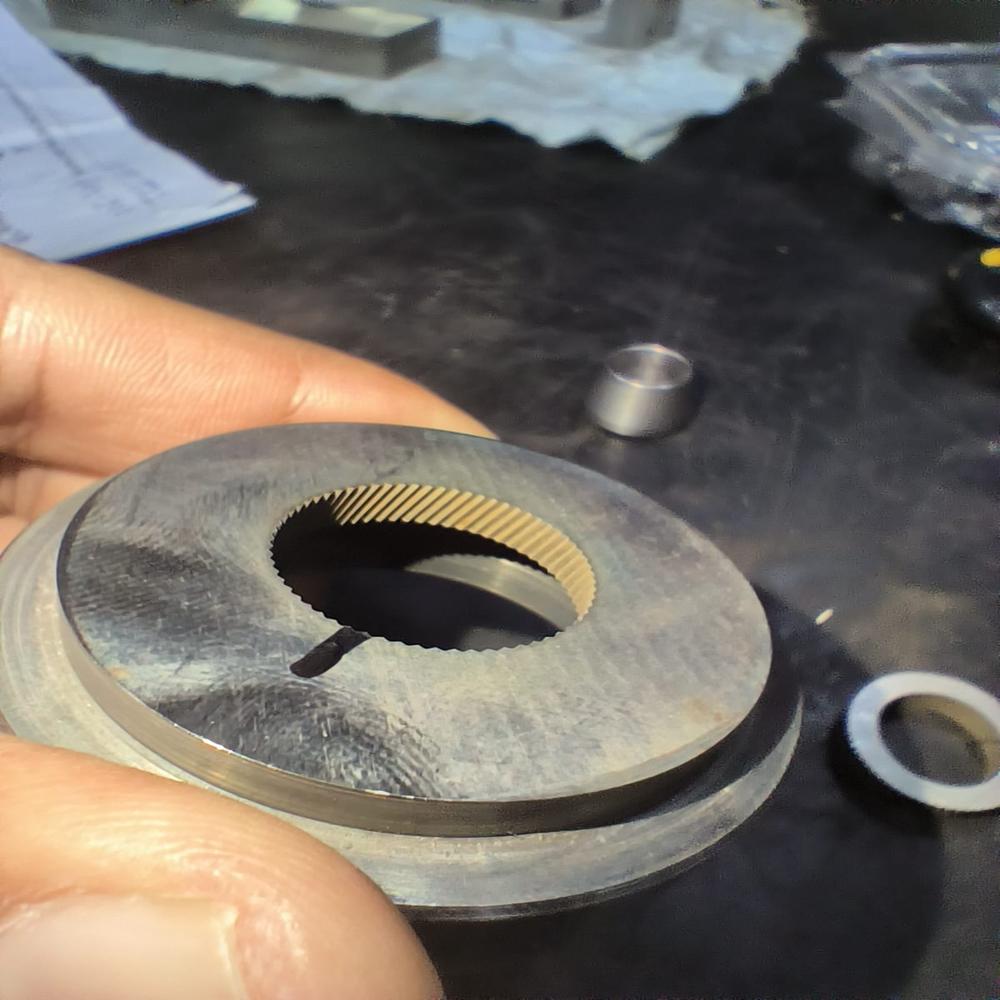

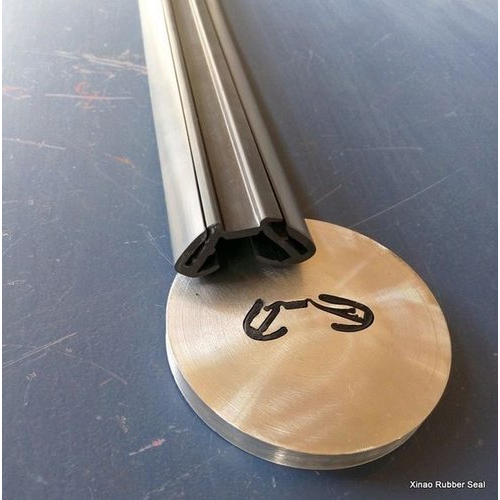

Tip and die for the cable industry are precision-engineered tools essential for the manufacturing and processing of cables. They are custom-designed to fit specific dimensions and production requirements, ensuring optimal shaping, forming, and cutting of cable components.

Description of Tip & Die for Cable Industry

-

Material:Typically made from hardened steel, tungsten carbide, or high-strength alloys to withstand extreme pressure and wear during extrusion and cable shaping processes.

-

Function:The tip acts as a guide for molten or extruded material, while the die shapes the cable profile as the wire or conductor passes through, ensuring uniform diameter and insulation thickness.

-

Applications:Used extensively in electrical, telecommunications, and construction industries for producing cables with precise dimensions and consistent quality.

-

Design Features:

-

Custom sizing to match cable specifications including round, multi-tip, or complex profiles.

-

Mirror-polished surfaces and smooth edges for optimal material flow and reduced wear.

-

Precision concentricity to maintain cable uniformity and electrical performance.

-

-

Performance:Durable under high-speed extrusion processes, maintaining shape accuracy with minimal downtime for tool replacement.

Key Benefits

-

Ensures accurate cable diameter and insulation thickness.

-

Enhances efficiency in cable extrusion and manufacturing lines.

-

Prolonged tool life due to wear-resistant materials.

-

Supports various extrusion techniques including pressure, tubing, and semi-pressure extrusion.

Price 5000.0 आईएनआर/ Number

- Minimum Order Quantity

- Supply Ability

- Delivery Time

- Main Domestic Market

- Main Export Market(s)

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें